| |

DCU Coke Drum Yield Strength Matching

Delayed Coker Unit drums operate in a severe operating environment with drum temperatures

reaching 510 °C [950 °F] and subject to quenching with water at 120 °C [250 °F] with resulting

upper bound strains reaching 6,500 µstrain (0.65%); hence, drum and skirt cracking is expected to eventually occur.

Many attempts to improve drum reliability have been derived intunitively; e.g., progressivley increasing Cr content from

C - ½ Mo to 1 Cr - ½ Mo, 1¼ Cr - ½ Mo, then 2¼ Cr - 1 Mo and even 3 Cr - 1 Mo

materials. These increasing Cr contents were apparently motivated by the accompanying increased yield strength; evidently,

a heurestic approach not demonstrated by documented study.

API TR 934-G attempts to describe another heurestic approach to drum bulging and cracking by recommending

the use of 1¼ Cr - ½ Mo (SA 387 11 Class 2) or 2¼ Cr - 1 Mo (SA 387 22 Class 2) plate materials.

Interestingly and amusingly, US patents have been registered for the use of these higher yield strength materials.

In addition, TR 934-G indicates that these plates can achieve higher minimum specified yield strengths in their Class 2 condition,

on the order of 415 MPa [60 ksi], from which, therefore, a greater resistance to bulging may be achieved.

This exceeds the SMYS of 310 MPa [45 ksi] per ASME II for both plate materials, in their Class 2 condition,

and needs to be specifically requested in the material order.

TR 934-G then suggests that plate arrangement (Figure 12 in API TR 934-G) be made to ensure adjacent plates limit differences

in yield strength to 41 MPa [6 ksi]. The TR also states that specifying these high yield strengths in plate makes them "easier"

to match to welding consumables. This suggests that yield strength matching is intended to extend to plate-weld joints, as well.

Validity of Yield Strength Matching

The notion that higher yield strength may provide benefit by delaying permanent bulging is appealing. The yield point is defined

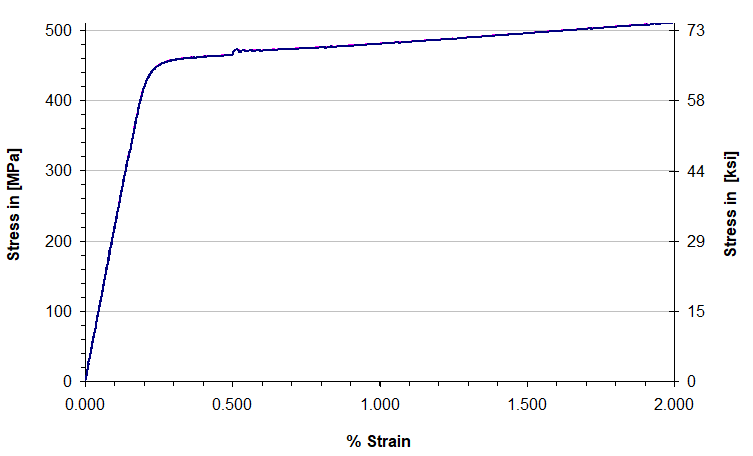

by the 0.2% offset or 0.5% extension under load (EUL) methods. Let's review the stress - strain curve for

one of the preferred materials. Figure 1 shows the monotonic stress strain curve for 1¼ Cr - ½ Mo (SA 387 11 Class 1

showing that yielding occurs at 0.2% or 2,000 µstrain at ambient; this reveals that Class I material may well have typically much higher

actual yield strength (YS) than SMYS. Yield point strain at temperature will be less, about 1,885 µstrain.

The strain levels occurring in a drum undergoing quench have been stated to have an upper bound of some 6,500 µstrain;

[0.65% strain] and, about 25% of quench exposures exceed 2,000 µstrain. Does this mean the higher specified yield strength material

and strength matched plate-to-plate and plate-to-weld will result in longer lasting bulge and crack free coke drums?

Arguably, a minimal yes; practically, no.

|

Figure 1 Stress - Strain Curve for 1¼ Cr - ½ Mo

Class I Material

|

|

Notes to Figure1:

SA 387 11 Class I material ordered without further specification; SMYS per ASME II is 242 MPa

[35 ksi] but MTR tested at 448 MPa [65 ksi].

Recall that SMYS values are based on industry wide sampling of mill product and may

sample at much higher actual values for a particular mill and heat; as demonstrated

by the figure for this sampling of SA 387 11 Class 1 material.

Note also that this is a monotonic stress - strain curve, the results from cyclic testing may

differ substantially from monotonic tesing and makes redundant the

efforts for "yield strength matching" as suggested per API TR 934-G.

|

|

Does API TR 934-G Have a Point with the Strength Matching Concept?

It doesn't seem so. As with other initiatives to improve coke drum reliability, this one also falls short. The TR does not

reference any citations as to the source of this suggestion. Rather, it appears to be another heurestic and anecdotal

attempt as some other prior developments over the last 60 years, some successful and others, not.

It has been well over 30 years since API conducted a major survey of the industry; the accumulated experiences and developments suggest

that another survey is due. With the abundance of learnings over that time frame, a number of valuable questions can be included in

a new survey to help utilize this equipment to a robustly established end-of-life.

The details for implementing design and design check methodologies for DCU coke drums are covered in detail in our course

John Aumuller, P. Eng., Ph. D.

|

|

| |