On Using API 579 FFS Project Ω and Larson Miller Methodologies

Catalyst tubes of steam methane reformers operate at very high temperatures and are, thus,

subject to creep failure. Design practice for tube pressure thickness uses a creep rupture

criterion, typically the minimum creep rupture strength listing from API Standard 530.

The standard covers a number of materials from carbon steel through HK-40 (25Cr - 21Ni) alloys.

In addition, although not included in that standard, superior alloys of HP (25Cr - 35Ni) grades

are used to extend operating temperatures to some 2,000 °F [1,093 °C].

The API 530 methodology intends to provide a minimum design life of

some 100,000 hours. However, in actuality, an average life extending to some

300,000 to 400,000 hours or better may be realized, i.e., the statistical variation

in actual service life.

In order to manage inspection, repair and replacement scheduling, it is necessary to initially

design to standard practice. Once in service, service life is affirmed using creep rupture

damage mechanics principles. Over the last two decades, API 579 - 1 / ASME FFS - 1 has provided

two alternative industry standard approaches, the MPC Project Omega methodology and the

Larson-Miller Parameter (LMP) methodology.

The Case for Project Ω Methodology

The API 579 / ASME FFS standard appears to favour the former since it claims that prior exposure

history is not required to estimate a remaining life. To effect this, a sample of tube must

be retrieved and subjected to creep testing in order to determine Omega material parameters.

These will implicitly take into account the to-date creep damage associated with past operation

The Case for the Larson-Miller Parameter Methodology

In contrast, the LMP method requires knowledge of planned or experienced operating history.

This should not be an issue for most industrial users with operations integrity management (OIM)

programs; historical pressure and temperature readings will normally be available in data archives.

Should this not be the case, particular NDE methods can establish a fairly accurate assessment of

through-thickness damage from which in-service remaining life estimates may be benchmarked.

NDE contractors have demonstrated success over two decades in characterizing this creep damage.

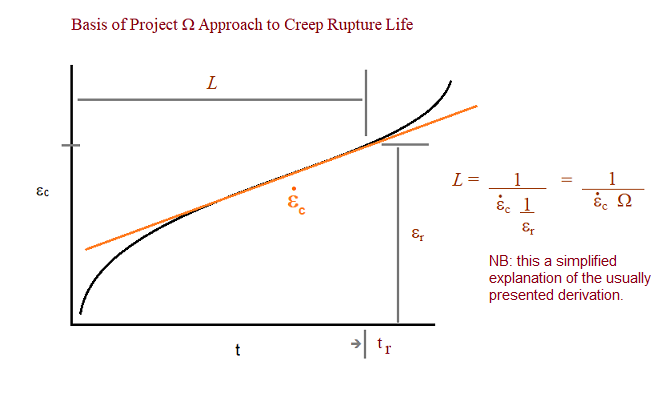

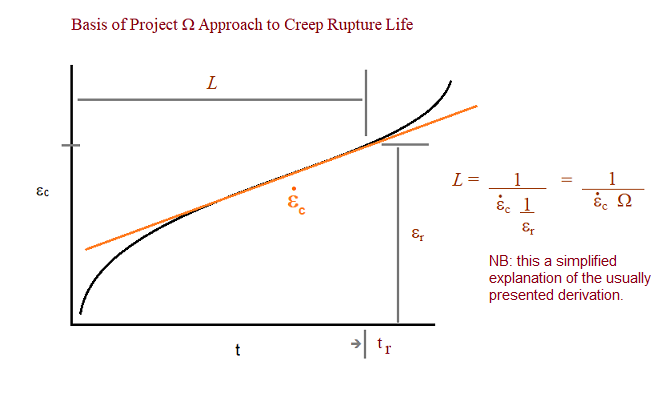

Project Ω Methodology is Complicated

The Project Omega approach requires stress, temperature and calculation of a

number of parameters that obscure the mechanics of the creep damage mechanism.

Some of these appear to be arbitrary, "convenience" or conditioning

factors e.g., accounting for component geometry. Some parameters are more descriptive

than quantitative such as adjusting the creep strain rate for the "bottom or top of the

scatter band"; the use of a spreadsheet or computer program is advised. Forward

planning from inspection and risk-assessed repair / replacement decisions may be thereafter

completed.

The LMP Approach: Simple, Elegant

A major advantage to the LMP method is its simplicity requiring only stress and temperature

and the established Larson-Miller parameter and constant values. The LMP data can be found conveniently

in API 530 and API 579 for various materials and is well supported in the open literature. One can then,

by simple hand calculation, bound a range in life expectancy from minimum (95% confidence) to average.

Forward planning from inspection and risk-assessed repair / replacement decisions may then be completed.

While the LMP method has several decades of documented and transparent research, in contrast, again,

the Project Omega methodology does not appear to provide the same courtesy for practitioners who,

consequently, appear to be at the mercy of the Project Omega cookbook approach.

The results from either methodology are comparable and similarly effective; unfortunately, HP alloy material

properties are not included for either methodology. This needs to be addressed by the appropriate

standards bodies to ensure the integrity of user's operations may be adequately and effectively managed.

Contact the writer for additional insights and consider our class covering Part 10

John Aumuller, P. Eng., Ph. D.

| |

|